Splicing Fiber Optic Cables is the process of joining two fiber strands so data can travel smoothly without signal loss. When done correctly, splicing creates a strong, clean connection that keeps internet, phone, and data systems working fast and reliably. This process uses trained skills, precise tools, and careful testing to make sure light signals stay clear as they pass through the cable. Good splicing improves network strength, reduces downtime, and supports long term performance for homes and businesses.

Understanding the Importance of Fiber Optic Cables in Today’s World

Fiber optic cables support many parts of our daily life. They carry the signals that help us stream videos, make calls, play online games, and share information between homes, schools, stores, and large companies. These cables work by sending light through thin glass strands. Because light travels very fast, fiber optic networks offer high speed and low delay. The technology is reliable, energy efficient, and ready for the future.

When a fiber cable breaks or needs to be extended to reach a new place, it must be joined with another cable. The connection point must be strong and very clean so the light signal can pass through without getting weak. This is why the process of Splicing Fiber Optic Cables is so important. A high quality splice helps keep services running smoothly even when cables are damaged or need upgrades.

Technicians who work with fiber optic cables need steady hands, technical skill, and proper equipment. A single mistake can affect the whole network. Because of this, homeowners and businesses rely on professional teams who understand the full process from start to finish.

Why Fiber Optic Splicing Matters: Ensuring Quality Connections

Fiber optic splicing matters because it protects the flow of data. When fibers are joined correctly, the light signal moves straight through the splice with very little loss. If the splice is not clean or lined up well, the signal can weaken. This leads to slow speeds, dropped connections, or repeated service issues.

A strong splice supports:

- Faster and more stable internet

- Reliable phone and security systems

- Cleaner data transfer for business operations

- Better long term performance with fewer repairs

- Reduced risk during weather changes or cable movement

Good splicing also lowers future costs. A clean splice lasts longer and reduces the need for repeated maintenance. Over time, this gives companies and families greater value from their network investments.

What is a Fiber Splicer?

A fiber splicer is a tool and also the name for the professional who performs the splicing. The tool is designed to hold the fibers in place and bring them together in a very precise way. It lines up the glass cores inside the cable so the light stays on a smooth path.

The professional splicer must understand how to clean fibers, prepare them, and test them after joining. Even small dust particles can cause problems. This makes training and experience very important. Skilled splicers follow strict steps to make sure that each joint is strong and safe.

Modern splicing tools use small cameras and exact alignment systems to bring the two ends together. This makes the results more accurate than doing it by hand.

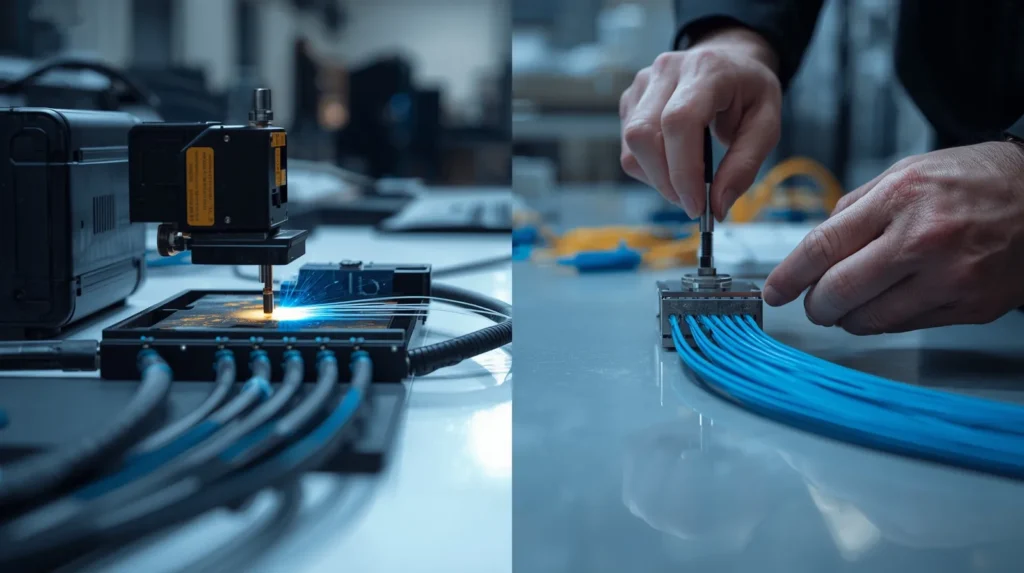

Types of Fiber Optic Splicing: Fusion vs. Mechanical Splicing

There are two types of fiber optics splicing that technicians use. Each method has its own purpose and benefits.

- Fusion splicing uses heat to melt the ends of the fibers together. This creates a very strong and clean joint. Fusion splicing has the lowest signal loss and is used for most permanent installations. It works well for long distance networks and high speed communication systems.

- Mechanical splicing holds the two fiber ends in a small connector device. The fibers do not melt. Instead, they are lined up closely and kept in position by the device. This method is faster and easier for temporary repairs or small projects. However, mechanical splicing may have slightly more signal loss compared to fusion splicing.

Choosing the right method depends on project size, performance needs, and budget.

How Does Fiber Optic Splicing Work? The Process Explained

Splicing is a careful process that requires full attention. The goal is to bring two fiber ends together without damaging the glass core.

The steps include:

- Cable preparation

The outer layers of the cable are removed. This exposes the thin glass fibers inside. - Cleaning the fiber

The technician wipes the fiber with special cleaning materials. This step removes dirt or oil that could affect the signal. - Cleaving the fiber

The ends of the fiber are cut in a smooth, straight way. A clean cut is needed for the splice to work well. - Aligning the fiber ends

The splicer tool brings the fibers together with high accuracy. Cameras help center the cores. - Creating the splice

For fusion, a small arc of heat melts the fibers together. For mechanical, the ends are joined inside a connector. - Protecting the splice

A heat shrink sleeve is placed over the splice to keep it safe from bending, dust, and pressure. - Testing the connection

The technician uses tools to check signal strength and confirm the splice is stable.

Each step affects how well the network performs, so precision matters.

Choosing the Right Fiber Splicing Method for Your Project

Different projects have different needs. Large internet lines, business networks, or long distance cables usually need fusion splicing because it gives the best signal quality. The joints last for many years and handle outdoor conditions well.

Smaller repairs, indoor jobs, or quick fixes may use mechanical splicing. It takes less time and does not need a fusion machine. This makes it useful for short term work or emergency service situations.

A professional team can guide you through which method is the best fit. The right choice helps protect both speed and durability.

The Role of Fiber Splicers in Reliable Connections

Fiber splicers do more than just join cables. They make sure the entire connection system is set up for success. Their role includes choosing the right tools, preparing the cables, testing the final results, and making sure the network follows industry safety standards.

They also understand how temperature, moisture, and cable bending affect fiber performance. Their skill helps prevent weak points that could cause outages in the future.

A trained splicer also documents the work and labels cables so that future upgrades or repairs are easier and more organized.

Common Challenges in Fiber Optic Splicing and How to Overcome Them

Splicing requires clean conditions. Dust, dirt, and moisture can harm the fibers. To overcome this, technicians work in controlled spaces and use protective equipment.

Another challenge involves fiber damage from bending or pressure. Fibers must be handled with care. Technicians use proper cable trays, flexible routing, and protective coverings.

Weather may also affect splicing conditions. Outdoor jobs sometimes require tents or covers to avoid wind and dust.

Other challenges include:

- Poor alignment

- Incorrect cleaning

- Damaged connectors

- Weak protective sleeves

Skilled technicians know how to avoid or fix these issues so the network stays strong.

How to Maintain Fiber Optic Cables After Splicing

Good maintenance protects the life of the splice. Regular checks help find early signs of weakness. This includes visual inspections and simple signal tests.

To maintain fiber cables:

- Avoid sharp bends

- Keep cables clean and dry

- Use proper routing clips or trays

- Do not place heavy items on cables

- Label cables clearly for future work

These basic steps improve signal quality and lower the chance of future damage.

Why Choose Heritage Cabling for Your Fiber Optic Splicing Needs in Dallas

heritage cabling has real field experience in handling fiber networks for many types of clients. Their team uses careful methods and modern tools to ensure each splice is clean, strong, and ready for long term use. They care about quality and clear communication with every customer.

Working with a team that understands both the technology and the needs of local clients helps you avoid costly mistakes. heritage cabling offers steady service, honest guidance, and dependable results for fiber projects of any size.

Contact Heritage Cabling: Get Expert Fiber Optic Splicing Services Today

If you want a network that stays strong and reliable, reach out today. You will get friendly support, clear answers, and expert service that protects your system and keeps your connection moving fast without interruptions.