What Is a Fiber Optic Cable Splicer and Why Does It Matter?

A fiber optic cable splicer is someone trained to connect two fiber optic cables. These cables carry light signals that allow people to use the internet, make phone calls, watch TV, and more. Without good splicing, the light signal gets weak or lost, which can make connections slow or not work at all.

Think about when a road is broken, and a construction crew must fix it. If the road isn’t fixed well, cars can’t drive smoothly. Splicing is the same idea—but with light inside a cable. The splicer has to join the cables so that the light moves like nothing ever happened.

Splicers often work on new buildings, towers, underground cables, and even high-speed train or airport systems. This makes their job very important in today’s world where everything runs on fast, clear signals.

The Evolution of Fiber Splicing in Today’s Digital World

Technology changes fast, and fiber optics is a perfect example. Years ago, internet signals moved through copper wires. These were fine for landline phones and dial-up internet, but not for streaming videos, online games, or big data.

Fiber optic cables changed everything. They use thin strands of glass to carry light instead of electricity. This makes them much faster and more reliable. As fiber became more popular, the need for splicing grew too.

Early splicing machines were big and hard to carry. Now, they are small enough to fit in a bag. Today’s splicing machines are automatic. They align the fibers using lasers and melt them with an electric arc—all in seconds.

This means companies can install fiber networks faster and fix problems quickly. People now expect internet to work 24/7, and splicing helps make that happen.

What Is Splicing in Optical Fiber?

Splicing in optical fiber is the process of joining two fiber optic cables. These cables carry light signals over long distances. If a cable is too short, damaged, or needs to be split into other lines, it has to be spliced.

You might be wondering, why not just plug it in like an electric wire? That’s because fiber optics are not just wires. They’re glass. And glass doesn’t just “plug in.” It needs to be aligned and fused carefully so the light doesn’t bounce, bend, or break.

In homes, offices, and giant data centers, splicing keeps everything connected. Without it, your internet would slow down or stop.

Types of Splicing Methods Used in Fiber Optic Work

There are two main splicing methods used by professionals today:

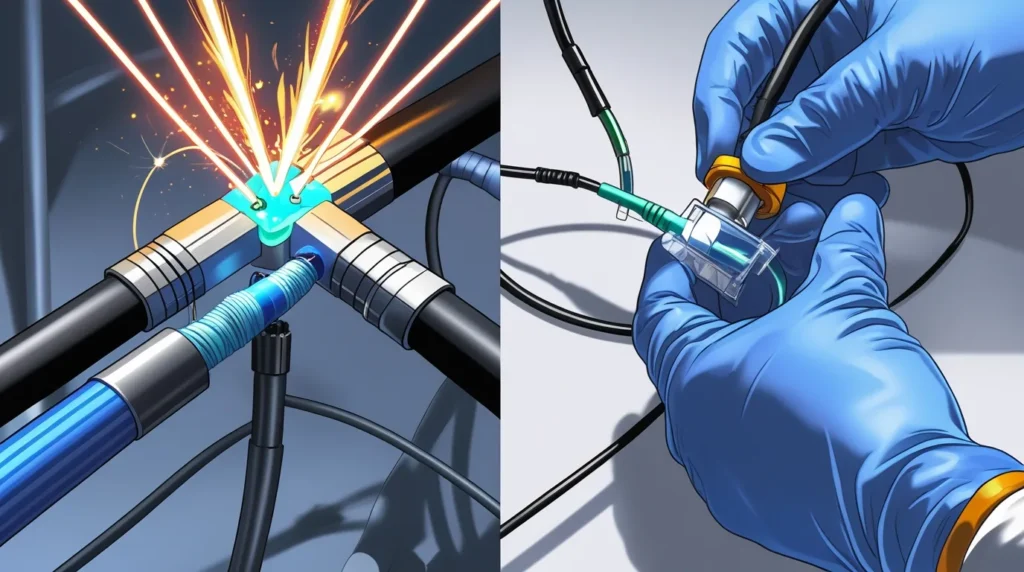

1. Fusion Splicing

This method melts the ends of the fiber optic strands together using heat from an electric arc. The two ends form a single, strong connection. This process is:

- Permanent

- Clean

- Low in signal loss

Fusion splicing is the most reliable and is used for outdoor cables, long-distance lines, and heavy data areas like hospitals and banks.

2. Mechanical Splicing

This is a quick method where the fiber ends are lined up inside a small plastic or glass connector. A gel helps the light pass through. No heat is needed.

It’s good for:

- Emergency repairs

- Quick fixes

- Indoor or small jobs

But it’s not as durable. Over time, dust or movement might break the connection.

Understanding Fusion Splicing Fiber Optic Cable

When people say fusion splicing fiber optic cable, they mean melting the fiber ends together with a tool called a fusion splicer.

Here’s a real-world example: A new shopping mall is being built. Internet lines need to go from the main road into the mall. The cables are too short, so a splicer comes in and joins them using fusion. After testing the signal, the connection is perfect—and shoppers enjoy free Wi-Fi when the mall opens.

A fusion splicer has cameras, motors, and a heating part. It:

- Lines up both fiber ends

- Checks them with lasers

- Melts them with electric heat

- Covers the joint with a sleeve for safety

This job might sound small, but each splice could support hundreds of internet users.

Can You Splice Fiber Optic Cable Without a Machine?

Some people ask, “Can you splice fiber optic cable if you don’t have the big machine?” Yes, but it’s harder.

The method is called mechanical splicing. You need:

- A fiber cleaver

- A splicing kit with holders and gel

- Alcohol wipes

- A light tester

You still have to cut and clean the fibers perfectly. Then you line them up in a holder and close the case. The gel inside helps the light move through the joint.

Mechanical splicing is handy for:

- Temporary setups

- Schools or offices with budget limits

- Training new splicers

But it’s not good for outdoor or long-term jobs. Rain, dirt, or heat can damage the joint faster than a fusion splice.

How to Splice Fiber Optic Cable: Step-by-Step Basics

Let’s look at a simple guide on how to splice fiber optic cable. Whether you’re a student, a new technician, or just curious, these steps show the care and detail needed.

Step 1: Prepare the Cable

Use a special cutter to remove the outside jacket. Be gentle—fiber is fragile.

Step 2: Strip the Buffer

Remove the colored coating to reach the glass core inside. This is usually just a few millimeters wide.

Step 3: Clean the Glass

Use alcohol wipes to remove any dust or oil. Even a tiny speck can ruin the splice.

Step 4: Cleave the Fiber

Use a cleaver tool to cut the ends flat. No angles or chips—just a smooth edge.

Step 5: Splice It

Place the ends in a fusion splicer or a mechanical holder. Follow your tool’s steps carefully.

Step 6: Protect It

Slide a sleeve over the joint and heat it. This protects it from water, pressure, and damage.

Step 7: Test It

Use a light meter or OTDR tool to see if the signal passes smoothly.

These steps take practice. Splicing isn’t just about tools—it’s about focus and clean work.

Splicing Fiber Cable in Internet and Phone Systems

Most people don’t think about what makes the internet work. But when they stream a movie, send an email, or call a friend, fiber optic cables are behind it.

Splicing happens in:

- Cell phone towers

- Neighborhood internet lines

- School and library networks

- Office buildings

- Highways and airports

An internet cable splicer may work in a bucket truck or underground box, splicing cables that connect homes to the larger network.

Phone lines are changing too. While many still use copper, new phone systems use fiber for voice-over-internet calls. Splicing phone cable is now part of both old and new technology.

What Tools Does a Fiber Optic Splicer Use?

Let’s break down the toolbox of a modern fiber optic splicer:

- Fusion Splicer: The main tool—melts and joins fibers.

- Mechanical Splice Kit: A backup for quick jobs.

- Cleaver: Cuts fibers cleanly.

- Strippers: Remove jacket and coating without damage.

- Microscope: Checks for dirt or cracks.

- OTDR Tester: Measures how well light travels through the splice.

- Cleaning Tools: Alcohol, lint-free wipes, canned air.

These tools are expensive and must be used carefully. Every job may require different gear. A good splicer is always prepared.

Challenges in Splicing Cut Fiber Lines or Damaged Cables

Let’s imagine a construction crew accidentally hits a buried fiber cable. Now, hundreds of homes have no internet.

A splicer is called in to fix it. Their tasks:

- Find the exact location of the break

- Dig safely to reach the cable

- Clean and prepare the ends

- Splice with precision

- Seal the cable against rain and dirt

- Test everything before leaving

Cut fiber lines are emergencies. Weather, animals, and even careless digging cause thousands of breaks each year. Fast response and quality splicing help avoid long outages.

It’s not just about fixing a cable. It’s about keeping people connected.

Why Heritage Cabling Is the Trusted Choice for Fiber Optic Cable Splicing in Dallas, TX

In a busy city like Dallas, TX, fast and reliable communication is vital. Businesses, hospitals, schools, and homes depend on smooth internet and phone service.

That’s why Heritage Cabling has become a name people trust. We work hard to deliver excellent fiber splicing whether it’s a new installation or emergency repair.

We use the latest tools, proven splicing methods, and well-trained teams. Our splicers know how to handle every type of cable—underground, indoor, outdoor, and aerial.

Heritage Cabling takes pride in:

- Clean, low-loss splices

- On-time service

- Friendly, skilled technicians

- Long-lasting work that meets all safety standards

Whether you need to build a fiber network or fix a cut cable, we’re here to help.

Need fast, clean, and reliable fiber splicing? Contact Heritage Cabling today. We’ll make sure your connection is strong, steady, and ready for anything.