Fiber optic cable installation is one of the most important steps in building today’s communication networks. It delivers faster speed, stronger connections, and reliability that old copper cables cannot match. This guide explains the full process, from planning routes to connecting fibers, in simple language. You will learn how cables are laid, how they are constructed, and how businesses benefit from these projects. With insights from experts and practical examples, the article provides a clear and complete answer for anyone curious about how fiber systems work.

Why High-Speed Connectivity Relies on Fiber Technology

Fast internet is no longer a luxury; it is a daily need. Every activity, from streaming movies to managing cloud-based systems, depends on stable connections. Copper cables once filled this role, but they struggle to keep up with modern demand. Fiber technology changed everything because it carries data using light instead of electricity.

Light signals move faster and can carry more information at once. Unlike copper, fiber does not weaken over distance. This means clear video calls, smooth online games, and quick downloads. Fiber also resists outside interference, so it stays reliable even in crowded cities. These qualities explain why high-speed connectivity relies on fiber technology today. Without it, many tools people use remote learning, telemedicine, cloud computing would fail to work properly.

As the world becomes more digital, fiber is the backbone. It supports new technology, from smart devices to artificial intelligence systems. Investing in fiber now ensures networks remain strong for decades to come.

Understanding the Basics of Fiber Cable Installation

Fiber cable installation begins with knowing what fiber optic cables are. A fiber cable is made of many thin strands of glass or plastic. Each strand carries light signals that hold data. These strands are delicate but protected by layers of coating, strength members, and an outer jacket.

When installing fiber, workers plan routes where cables will be placed. This could be underground, along poles, or inside buildings. Special tools are used to protect the fibers during placement, since even small bends can cause signal loss. Once installed, the cables connect to devices that turn light signals into information, like internet data or phone calls.

The installation process is different from copper wiring. Copper uses electrical signals, which can weaken over distance or be disturbed by outside interference. Fiber, however, provides faster speed and clearer signals, making it the preferred choice for modern systems.

Understanding these basics helps explain why professional planning and careful work are needed during installation. It is not just about placing a cable; it is about securing a system built for the future.

Fiber Optic Cable Installation Process Explained Step by Step

Fiber optic cable installation is a step-by-step process that ensures networks are strong and reliable.

Step 1: Planning and Design

The process begins with mapping the route. Engineers study the area, mark obstacles, and plan where cables will run. This stage includes permits, safety checks, and agreements with property owners.

Step 2: Preparing Pathways

Trenches may be dug for underground cables, or ducts and conduits are cleaned for placement. In some areas, cables may be strung along poles. The method depends on the environment.

Step 3: Cable Placement

Workers use pulling or blowing methods to place the fiber cables in the prepared pathways. Pulling involves guiding the cable through ducts with rope or machinery. Blowing uses compressed air to push the cable smoothly.

Step 4: Splicing and Connections

Fiber ends are joined together using splicing, a precise method that aligns glass cores so light passes without loss. Connectors may also be added to link cables with devices.

Step 5: Testing and Quality Checks

Once connected, special tools test the signal strength. Any weak points are fixed before the system is approved.

Step 6: Documentation and Handover

The final step includes recording routes and connections for future maintenance. The system is then handed over to the client.

Each step shows why professionals are needed. Precision, safety, and knowledge all play roles in delivering long-lasting results.

Laying Fiber Optic Cable: Methods Used by Professionals

There are several ways professionals lay fiber optic cable, and the method depends on the environment and project size.

Underground Trenching

Traditional trenching involves digging a path for cables. It is often used in rural areas where open land is available. Trenches protect cables but require careful sealing to prevent water damage.

Micro-Trenching

In cities, micro-trenching is popular. A narrow cut is made in roads or sidewalks, and cables are placed inside. This method reduces disruption to traffic and speeds up the job.

Duct and Conduit Systems

Many areas already have ducts or conduits from past utility projects. Fiber can be pulled or blown through these systems, saving time and reducing cost.

Aerial Installation

Sometimes cables are placed overhead, strung along poles. This is quicker but exposes cables to weather and physical damage.

Each method requires different tools and planning. Choosing the right one ensures fiber stays safe while delivering reliable service.

Optical Fiber Installation and Its Growing Role in Modern Networks

Optical fiber installation has become central to building strong communication networks. It supports industries, governments, and communities by ensuring information moves quickly and securely.

In homes, fiber means faster internet for learning, gaming, and streaming. In businesses, it powers online tools, cloud systems, and video meetings. Schools use fiber to connect students to resources worldwide. Hospitals rely on it for telemedicine and quick sharing of medical records. Even smart cities use fiber to link traffic lights, cameras, and sensors.

The growing role of optical fiber shows in its expansion worldwide. Countries invest in national projects to bring fiber to every home and office. Without it, economies risk falling behind. Fiber also supports the shift to 5G, which depends on strong backhaul networks.

Simply put, optical fiber installation is not just about cables. It is about building the foundation for modern life.

How to Install Fiber Optic Cable Safely and Efficiently

Safety and efficiency are top priorities in fiber optic installation.

Worker Safety

Installers wear protective gear, including gloves and glasses, since glass fibers can cause injuries. They also follow rules to handle tools carefully.

Cable Handling

Cables must not bend too tightly. Even a small bend can block signals. Workers use rollers, guides, and specialized equipment to protect cables.

Splicing and Termination

Splicing requires precision. Fibers are joined in clean environments to avoid dust and misalignment. Tools like fusion splicers melt fibers together with accuracy.

Testing for Performance

After installation, tests check signal strength and quality. Problems are fixed immediately, ensuring the system works before it is used.

By following these steps, fiber optic cable installation is completed safely and on time. The result is a network that lasts for decades with minimal maintenance.

Laying Fiber in Construction Projects: What You Need to Know

Fiber plays an important role in construction projects. Planning ahead is critical.

Builders often create pathways for fiber early in the project. Installing ducts during foundation work makes adding cables later easier. Without this step, workers may need to cut walls or dig up roads, increasing cost and disruption.

For large projects, fiber supports key systems. Security cameras, alarm systems, and internet services all rely on it. Office towers, residential complexes, and hospitals all use fiber from the start to ensure reliability.

Construction teams also follow strict codes. These rules cover safety, performance, and placement. Codes prevent hazards, such as cables overheating or being damaged by heavy equipment.

Knowing how fiber fits into construction helps save money and time. Early planning means stronger networks and smoother building operations.

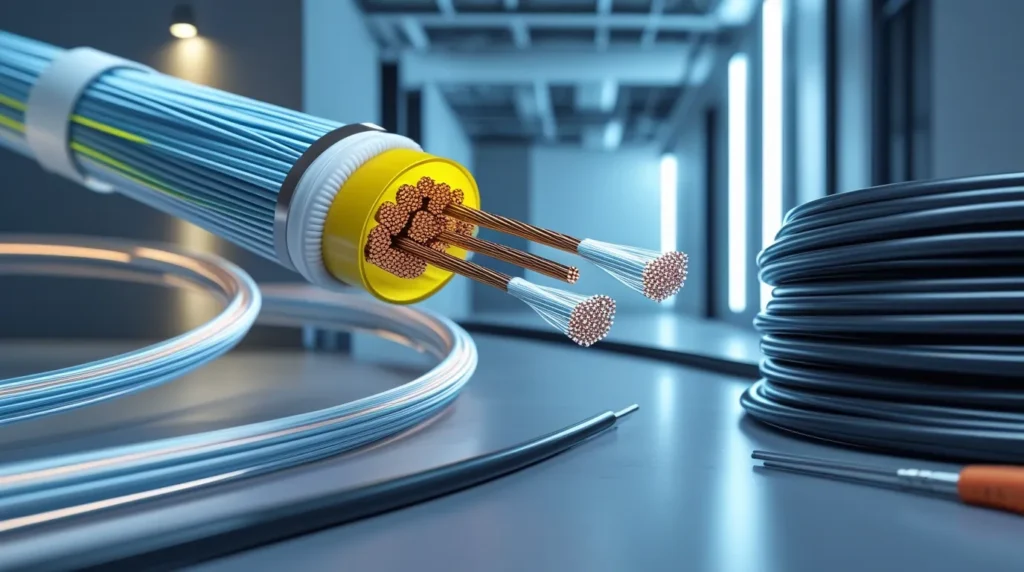

Construction of Fibre Optic Cable and Its Key Components

The construction of fibre optic cable makes it both delicate and strong.

Core

The thin glass or plastic strand that carries light signals.

Cladding

A layer around the core that reflects light back inside, keeping signals from leaking.

Buffer Coating

Protects the core and cladding from scratches or moisture.

Strength Members

Often made of Kevlar or similar materials, these prevent stretching or pulling damage.

Outer Jacket

The outermost layer, designed to withstand weather, heat, and impact.

Together, these components allow fiber cables to carry massive amounts of data while lasting for decades. The design makes them resistant to most environmental conditions.

Without this structure, the fragile glass strands would break easily. Thanks to careful construction, fiber cables remain one of the most reliable parts of modern infrastructure.

Fibre Optic Projects That Drive Business Growth in Dallas, TX

Fibre optic projects power business growth by giving companies faster, more reliable connections. In Dallas, TX, expanding fiber networks help companies compete in global markets.

For small businesses, fiber enables quick communication, smooth payment systems, and stronger online presence. For large organizations, it powers cloud storage, video conferences, and customer support systems. Fiber also reduces downtime, saving businesses money.

These projects often involve partnerships between governments, providers, and contractors. Together, they build infrastructure that benefits the entire city. Over time, the presence of strong fiber networks attracts new companies, boosting economic growth.

For businesses, investing in fiber is not just about today. It is about preparing for future technology, from artificial intelligence to smart logistics. Fiber optic projects are the path to long-term success.

Choosing Heritage Cabling for Professional Fiber Optic Cable Installation

Heritage Cabling has years of experience in fiber optic cable installation. Their team understands the full process, from design to testing. They use modern equipment and proven techniques to ensure reliability.

By working with Heritage Cabling, clients benefit from a company that values safety, trust, and long-term results. Whether the project is small or large, the same care and attention to detail are applied. Their expertise ensures networks are built for today’s needs and tomorrow’s challenges.

Choosing the right company makes the difference between weak connections and strong performance. Heritage Cabling offers the professional service needed to stay connected.

Conclusion

Fiber optic cable installation is the backbone of modern communication. It provides faster speeds, stronger reliability, and long-term benefits for both homes and businesses. While the process involves many steps, from planning to testing, it becomes smooth with experienced professionals.

If you want your network built for the future, choose experts who care about quality and trust.

Contact Heritage Cabling today and learn how our fiber solutions can support your needs with lasting results.